top of page

Amazon

Building panels

This collaborative venture with Amazon aims to develop a closed-loop recycling process that converts post-industrial logistics fabric waste into high-performance acoustic and hard panels. The project focuses on discovering innovative methods to repurpose hard-to-recycle fabrics into new products and marketable opportunities.

From warehouse pods to panels

The system had a wide mix of materials and contaminations, meaning the PODs became impossible to recycle through standard recycling processes. The project addresses the need for scalable processes that can manage high volumes of waste while identifying globally demanded product applications. Since these fabrics cannot be recycled into new textiles, the alternative solution is to convert them into interior panels for acoustic purposes and wall coverings, preserving as much value as possible. The ultimate goal is to create fully recyclable panels that meet industry standards.

Material development process

This initiative faces two primary challenges: transforming multi-material waste from Amazon’s logistics fabric into felt, and designing durable panels suitable for mass production. The key is to create a material that is efficient to produce, scalable, and high-quality, making it a competitive alternative to other products on the market.

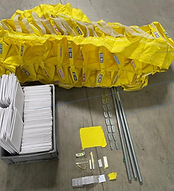

Waste collection

Material separation

Fiber opening

Non-woven felt

Panel production

Collecting POD system, analyse and separate the contaminants such as metal

The fibers where shredded and the hard plastic separated further

The shredded fibers, separated from the plastic went through an additional fiber opening process

The fibers were processed with a recyclable binder solution and processed into felt

The felt were later on heat pressed into products such as acoustic panels.

Product outcome

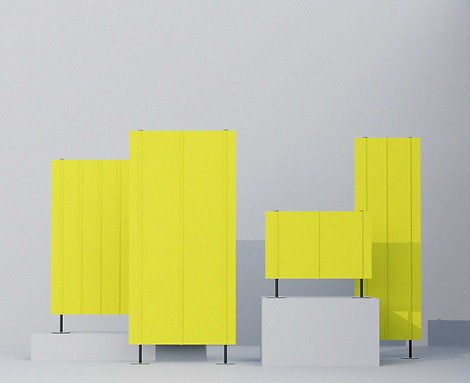

Acoustic Panels

This project confirms the feasibility of a scalable process for producing acoustic and hard panels entirely from recycled fabric waste. Performing acoustic tests, it was proven to provide acostic performance required in office spaces.

Alternative outcome

Construction panels

The hard panels allow us to enter a market where the volume demand is high, and the applications are many. As designers of modern office spaces often look for unique and sustainable look with a strong story, this panel has a potential of becoming a solid product offer for a growing market.

bottom of page